- Metals & Cable Plant Machinery Installation ( CCR Line etc)

- Cable Conductor Wire Plants

- Primary Aluminium Smelter

- Secondary Aluminium Smelter

- Extrusion Industry

- Gravity Die Casting

- Pressure Die Casting

- Copper & Copper Alloys

- Zinc

- Iron & Steel Foundries

- Batch Ageing & Heating Oven For Alloy Wires

- Copper & Aluminium Rods

Continuous cast rod line installation (Aluminum and Copper)

Engineering Consultancy and Project Management for Aluminum Rod Rolling Mill Installations Manufacturing project More than 16 Nos Aluminum Rod Rolling Mills Installations carried out / Under progress in various sites at Indigenous & Overseas Projects of Original Properzi make / Chinees make / Indigenous made Mills of various Capacities for Aluminum rods of EC / Alloy grade.

⦾ Engineering Consultancy & Project Management.

⦾ Design, PMC, Erection & Commissioning (Turnkey solution) services,

⦿ Aluminum CCR rolling line for EC/Alloy grade(series1XXX/6XXX/8XXX/1120/AL59).

⦿ Copper CCR line.

⦾ Engineering and Construction services to Project site in Application assessment, post supply technical support,

⦿ Construction of Basement and Foundation for structural / Equipment’s.

⦿ Infrastructure Projects (Industrial sheds, Warehouses, Roads, Culverts & Drains).

⦿ Complex civil structures & Buildings.

⦿ MEP – Pipe line / Structural fabrication.

⦾ New Age Conductor Development Division

⦿ Technical & Metallurgical guidance related with Aluminum Rolling Mill & Casting sections etc

Before commencing the design and construction work (Includes the following services)

⦾ Shall visit and thoroughly inspect the Site and any structure(s) or other manmade features to be modified and become familiar with local conditions under which the Project will be constructed and operated.

⦾ Familiarize itself with the survey, including the location of all existing buildings, utilities, conditions, streets, equipment, components and other attributes having or likely to have an impact on the Project.

⦾ Familiarize itself with the Client’s layout and design requirements, conceptual design objectives, and budget for the Project.

⦾ Familiarize itself with the CLIENT’s layout and design requirements, conceptual design objectives, and budget for the Project.

⦾ Familiarize itself with pertinent Project dates and programming needs, including the Project schedule.

⦾ Review and analyze all Project geotechnical, hazardous substances structural, chemical, electrical, mechanical and construction materials tests, investigations and recommendations if required.

Cable Plant Machinery supply & installation (Rod Break down/stranding/Multiwire

⦾ Engineering Consultancy & Project Management.

⦿ Power Conductor.

⦿ Power Cable in LT / HT / EHV line

⦿ Consultancy for developing and manufacturing assistance of New Age HTLS Conductor.

⦾ Design, PMC, Erection & Commissioning (Turnkey solution) services,

⦿ Power Conductor Division.

⦿ HT / LT / EHV Power cable manufacturing Projects (Green field / brown field industries).

⦾ Engineering and Construction services to Project site in Application assessment, post supply technical support,

⦾ Construction of Basement and Foundation for structural / Equipment’s.

⦾ Infrastructure Projects (Industrial sheds, Warehouses, Roads, Culverts & Drains).

⦾ Complex civil structures & Buildings

⦾ MEP – Pipe line / Structural fabrication.

⦾ Shall visit and thoroughly inspect the Site and carry out Feasibility study of the existing plant and machineries to assess the operational capabilities to manufacture HTLS Conductors. This shall include the modification requirement of the existing plant and machineries / any requirement of additional machinery to facilitate the above particularly in Wire Drawing, Ageing, Stranding and Testing equipment facility.

⦾ Setting up of Design parameters for the selected Conductor.

⦾ Assisting procurement of machineries by finalizing technical specification, vendor identification for the steel core / Annealing facility

⦾ Finalizing and releasing the Conductor design / Cross sectional drawing / Die drawing etc for the selected HTLS Conductor.

⦾ Raw material sourcing and recommendation based on comparison of commercials of various raw material suppliers.

⦾ Assisting procurement of materials such as special Steels, Aluminum rods if any by for manufacturing of the selected HTLS conductor by finalizing technical specification, vendor identification.

⦾ Installation assistance of the modification of machineries if any

⦾ Coordinating the process work such as drawing / annealing / stranding / Test witness of wires, conductors.

⦾ Supervision and guidance for manufacturing 2 to 3 KM long HTLS Conductor production for Type Test

⦾ Type Test witness visit if any at 3rd party lab.

⦾ Carry out a systematic, critical appraisal of all potential hazards involving personnel, plant, services and operation method.

⦾ Ensure that Safety management system fully satisfies the legal requirement policies, objectives and program as well as relevant codes / standards.

⦾ Spirit of Technological exploration.

⦾ Forward Planning and forecasting to meet the growing demands.

⦾ Reliable partner with manufacturing capabilities, stringent quality systems and process controls.

Aluminum Dross Processing Machinery (Supply and Installation)

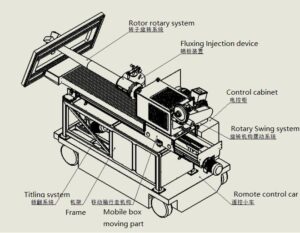

Aluminum Degassing rotary Fluxing injector (Supply and installation)

Developing and Manufacturing various Types of HTLS Conductor

⦾ ACSS

⦾ TACSR and STACIR

⦾ ACCC / ECFC- ENERGY COMPOSITE FIBER CORE

⦾ GAP conductors

⦾ Special Conductors T2 , AL59 etc.

New Age Conductor Development Division

⦾ Developing Aluminum Alloy wire rods such as 6201 type A2/A3/A4/1120 /AL59/AT1/AT3 etc. for conductors.

⦾ Aluminum-clad steel wire production technical guidance related to the procurement of steel wires for conductor manufacturing, steel rods used for Al-clad production, etc

⦾ Technical guidance with HTLS Overhead conductor inquiries through Tender and submit the files related to

⦿ GTP preparation.

⦿ Calculations submission through PLS CADD software.

⦿ Developing Die Design and Conductor Design Drawings

⦿ Guidance in manufacturing and type testing process.